Die Cutting

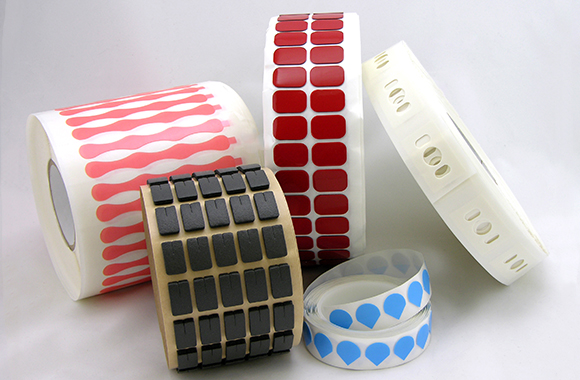

Budnick die cuts adhesive tapes, foams, and other and flexible materials to a variety of custom shapes and sizes that can be provided on a sheet or on a roll

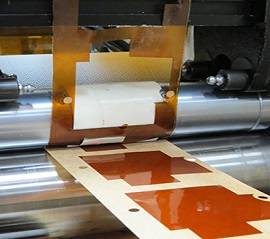

Rotary Die Cutting

Using precision engraved steel cylinders, we can quickly and easily die-, cavity-, kiss-, or butt-cut a wide variety of roll goods - both adhesive and non-adhesives tapes, foams, foils, plastics, and films up to 1/8" thick.

Flatbed Die Cutting

Flatbed die-cutting helps save money on tooling and accommodates thicker and softer material than most rotary methods allow. This process is ideal for shorter but still intricate production runs.

Specialized Capabilities

Advanced equipment allows us to minimize scrap and maximize runtimes and production efficiency - from longer length rolls and finger lift edges, to reduced scrap by spacing parts without a matrix.

What We Offer

We have the versatility to die cut almost any material with a multitude of different processes and hit customer specs every time. Each machine and operator have different qualities that line up with individual customer needs and our years of knowledge makes Budnick the best in the industry. Our rotary presses allow us to provide both roll and sheeted parts while holding the tightest of tolerances. The flatbed department can work with tricky materials and still provide the edge quality and product consistency of a tooled part. Whether you’re looking for a doubled coated die cut adhesive in roll form for long production runs or a less dense individual foam part with tight tolerances we’ll find the right process and provide the right part every time.

Budnick Die Cuts: Tape | Pressure Sensitive Materials | Silicone Rubber | Fabric | Label Stock | Plastic Liner | Plastic | Gasket Materials | UHMW | Foil | Non-Woven | Foam | Silicone Foam | Abrasive | Specialty Materials | Rubber & More

Case Studies

Budnick has developed a series of proprietary die-cutting processes that lead to cleaner, more accurate cuts. Read on to learn how else we've improved our customers' processes!

Security Panel Cover Attachment & Protection

Budnick's die-cutting capabilities and expertise with extended liners helped create user-friendly solutions for a major electronic automation and controls manufacturer.

- High bond 3M™ VHB™ Tape was die cut to the customer's exact specifications

- Added a 12 point liner that is stiff enough for easy release & and a finger-lift tab to simplify product assembly

- Designed packaging that would prevent shipping damage & also act as a dispenser unit for the parts

Case Study Environmental

A building materials manufacturer came to Budnick after experiencing failure with a tape they were using on their fiberglass insulation line.

- Used in a flying splice application, it needed to perform in extreme temperatures

- A double coated PET tape was found to work well in both winter and summer months

- A die-cut tab was supplied to the customer to better support the splice

Case Study Converting Experts

An automotive supplier could only purchase rolled product, but the application called for short pieces

- Sheets containing four individual pieces met the customer's need

- A custom die was made to cut parts to length with a minimum amount of bevel on the product

- The material maintained its cord, and the presentation saved production time